Ice*Meister™ Model 9734-REFR

OPTICAL DEMAND-DEFROST CONTROLLER

FOR COMMERCIAL REFRIGERATORS

Technical Data Sheet

Figure 1 — Model 9734-REFR demand defrost controller for commercial walk-in refrigerators and reach-in refrigerated display cases in supermarkets, restaurants, convenience stores.

9734 reacts to a light dusting of frost, virtually eliminating frost from evaporator coils. Relay contacts close immediately as frost appears on evaporator tube, defrost cycle starts . Blue indicator LED and relay contacts remain activated until defrost cycle is complete, then LED goes dark and contacts open when frost is gone, terminating defrost cycle. Self-indicating sensor probe glows frosty blue throughout defrost cycle.

GENERAL DESCRIPTION

Ice*Meister™ Model 9734-REFR is a demand-defrost controller that monitors the optical profile of refrigerator evaporator coils, senses frost and ice on the coils, and controls the refrigerator’s defrost cycle in response to the physical presence or absence of frost and ice. Initiates defrost cycles when required, suppresses defrost cycles when not required, holds defrost duration to an absolute minimum. Keeps food colder, minimizes operating cost.

9734 is completely self-contained. Robust, solid, no exposed electronics. Simple 4-wire interface. No moving parts. Rugged four-conductor cable exits downwind side of housing for interface to host refrigerator. Color-coded wires are conveniently stripped and tinned for universal use.

Power input is any clean voltage between 6 VDC and 35 VDC. Control output is a pair of normally-open, single-pole, single-throw relay contacts that control the defrost cycle. A blue indicator LED is displayed inside the clear plastic probe to indicate the presence of offending frost and the defrost cycle is ON.

No external components other than a power relay is needed to switch power between the host refrigerator’s compressor and defrost heater.

9734 replaces primitive defrost timers. It provides sensitive real time defrost control in response to the physical presence or absence of offending frost for commercial walk-in and reach-in refrigerators and all other self-defrosting chiller systems, large and small.

When the evaporator tube is frost-free, 9734’s output relay contacts remain open and the probe’s indicator LED remains dark. Immediately as the tube begins to accumulate offending frost, 9734 senses that frost, closes its output relay contacts, and illuminates the blue indicator LED. This signals the host power contactor to switch the compressor OFF and the heater ON, initiating a defrost cycle.

As soon as the defrost heater has melted the offending frost and the evaporator tube is frost-free, the defrost cycle terminates. 9734 output relay contacts re-open, and the blue indicator LED goes dark again. No needless heat is introduced into the chiller box at any time, keeping food colder, saving energy.

9734 controls any refrigerator’s defrost cycle in real time, sweeping back-and-forth across the frost-formation threshold, reducing defrost energy to an absolute minimum, reducing operating cost, and paying for itself in saved electricity.

The amount of offending frost required to initiate and terminate a defrost cycle is set at installation time by moving the 9734 housing either up or down, so the evaporator tube’s tangent line rides either higher or lower in the air gap.

9734 installs on any evaporator coil or refrigerator at the factory, or is retrofitted in the field as an aftermarket product. It eliminates all moving parts, reduces parts count, improves reliability, and pays for itself with saved energy.

9734-REFR reduces energy consumption, it …

● eliminates defrost cycles when there is no frost to be defrosted.

● initiates defrost cycles immediately as insulating frost appears on evaporator coils.

● terminates defrost cycles immediately as insulating frost is gone.

● minimizes defrost heat inside the refrigerator, so the compressor works less.

● keeps food colder, minimizes defrost heat inside the chiller box, improves efficiency.

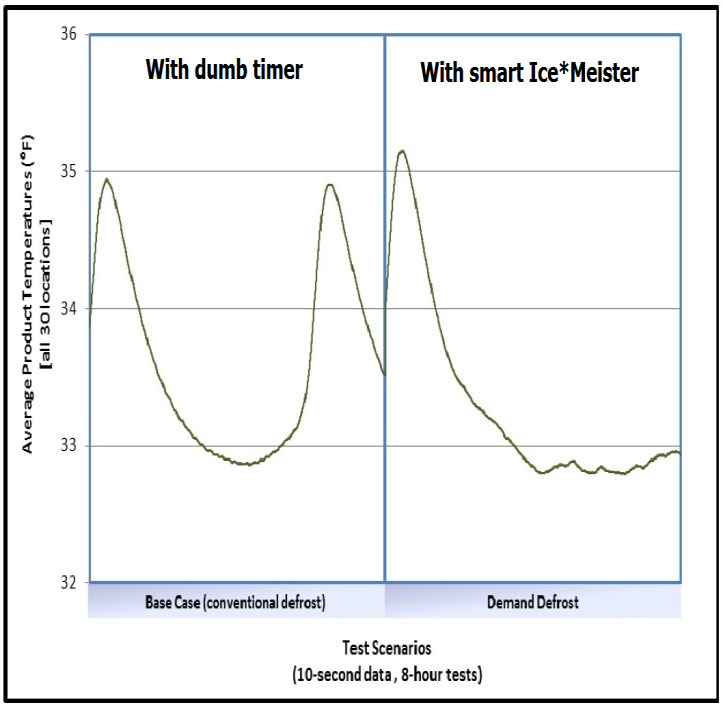

√ defrost cycles are shorter, more precise.

√ food temperature excursions during defrost cycles are more modest.

SPECIFICATIONS

SENSITIVITY TO FROST ACCUMULATION:

- Better than 0.1 inch of rime frost or clear ice.

ORIENTATION:

- Air gap must enclose the monitored evaporator coil, and face into the oncoming air flow.

OPERATING / STORAGE TEMPERATURE:

- -40 deg C to + 50 deg C.

ELECTRICAL INPUT:

- Any clean DC source between 6 VDC and 35 VDC

- Current draw: 100 mA max @ 24 VDC.

- red wire + 24 volts DC

- black wire – 24 volts DC, instrumentation ground

ELECTRICAL OUTPUT:

- 1 pair of single pole, single throw, normally open relay contacts,

- output for buffered control of compressor motor or evaporator-coil bypass valve

- Capacity 1 Amp, 50 volts non-inductive (see relay data sheet, below)

- Close when frost is present,

- Open when frost is absent.

- green and white wires = output relay contacts

VISUAL OUTPUT:

- Probe glows BLUE to indicate defrost cycle is ON and relay contacts are closed.

CONNECTING CABLE:

- 0.1 inch diam lightweight four-conductor shielded cable, stripped and tinned

- Red, black wires: + 24 VDC in

- Green, white wires: Relay contacts out

- Length: 6 feet

DIMENSIONS:

- Height: 2½ inches

- Width: 1¼ inches

- Depth: 1 inch

- Probe extension from housing: 1 inch

WEIGHT:

- 4 ounces